WOOD ELEMENTS cladding brings natural style to any exterior surface, whether as an individual feature or an entire façade.

WOOD ELEMENTS is a complete solution, offering not just the cladding but all the detailed trims required to finish off the project ensuring a watertight result.

Offering easy installation with its end matching, concealed screw fix, automatic spacing design and exclusive designer trims. Using our expertise in drying and machining timber enables us to manufacture not only an incredibly beautiful cladding, but also a precision piece of timber suitable for all the ELEMENTS.

All of Hurford’s WOOD ELEMENTS cladding is 100% PEFC Certified.

Species

Spotted Gum

Saligna

Blackbutt

Finish Options

Dressed Face

Sawn Brushed Face

Size

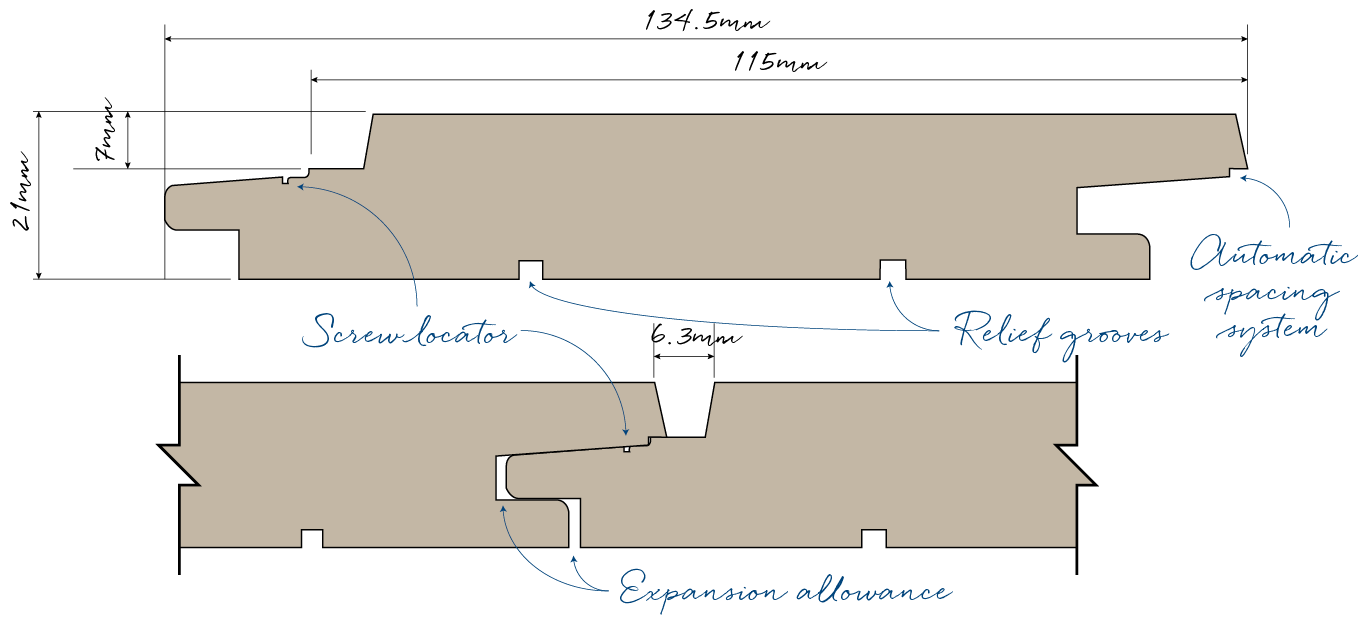

134.5mm (Cover Size 115mm) x 21mm

Designer Profile

WOOD ELEMENTS collective features include; a straight-line edging process to ensure the cladding is machined to a fine tolerance; relief grooves which are designed to take the stress out of the cladding; a specially designed ridge locater connects with the overlap line controlling the expansion allowance for any timber movement.

Designer Trims

WOOD ELEMENTS trims provide a streamline finish and play an integral part in ensuring a water tight finish. All aluminium trims are factory fitted with waterproof gaskets*, designed to decrease the on-site sealing process, and delivery of loose materials. WOOD ELEMENTS trims are available in a black powder coated chromate treated aluminium.

Design Points

WOOD ELEMENTS is a natural product, a renewable resource, providing an environmental advantage over common building materials. Timber will only perform within the limits of its natural properties, when specifying, it’s critical that the characteristics and properties of the timber are considered and determine how they will respond to the environment they are placed in.

Design Elements & Fixing

Extreme care has been taken in all aspects of WOOD ELEMENTS Refined Architectural Hardwood Cladding. From the environment to milling and drying, profile and trim design and species selection. Each element plays an important role in the performance of the cladding system.

More on Design Elements & Fixing

End Matched

Utilising a specially developed end match system for external use, WOOD ELEMENTS end-match profile has a micro bevel edge designed to encourage water to drain away from the join. End matching the product means the boards can be fixed mid cavity batten, eliminating the need to dock and create volumes of waste, saving a minimum of 10% of the product that previously would have been thrown away. Not only does this save costs, it’s a better for our environment with less resource being used.

WOOD ELEMENTS is a cladding that has been designed with concealed fixing in mind. For fixing, Hurford’s recommend screwing along the pre machined “screw location” line which enables the board to slip over the secured row quickly and easily, creating a clear face finish.

Automatic Spacing System

The Automatic Spacing System allows expansion to be placed between the boards, which is automatic and doesn’t require any special tools or spacers to get right. The specially designed ridge locator controls the expansion allowance. This unique design feature takes out any pressure caused if the boards expand due to absorption of moisture.

Double Dried Technology

All the timber used to manufacture WOOD ELEMENTS is air dried for up to 12 months to bring the moisture content down to “fibre” saturation. From this point the timber is kiln dried using double drying technology, developed by Hurfords to ensure significant added stability. This produces a finished product with a very narrow moisture variation.

Straight-Line Dressed

When timber is milled and dried it builds stress and force, which translates into spring and bow. Steps can be taken during this process to minimise this. Hurfords uses a process to straighten the boards post drying to ensure the boards are straight and stay straight. This ensures that WOOD ELEMENTS can be easily installed and all shadowlines remain as they have been designed – straight.

WOOD ELEMENTS Technical Information & Downloads

Wood Elements Brochure NZ

Wood Elements Installation Guide NZ

Product Disclosure – NZ Building Code Compliance

WOOD ELEMENTS Maintenance